Everything You Need to Know About End-of-Arm Tooling

End-of-arm tooling (EOAT) is the most important part of any robotic arm. This technology allows the robot to interact with its environment. It is a fascinating type of engineering, and learning more about it is essential for anyone interested in robotics and automation. In fact, EOAT is critical for the future of several industries. Beginners need to know all about end effectors, what they are used for and why they are indispensable.

What Is End-of-Arm Tooling?

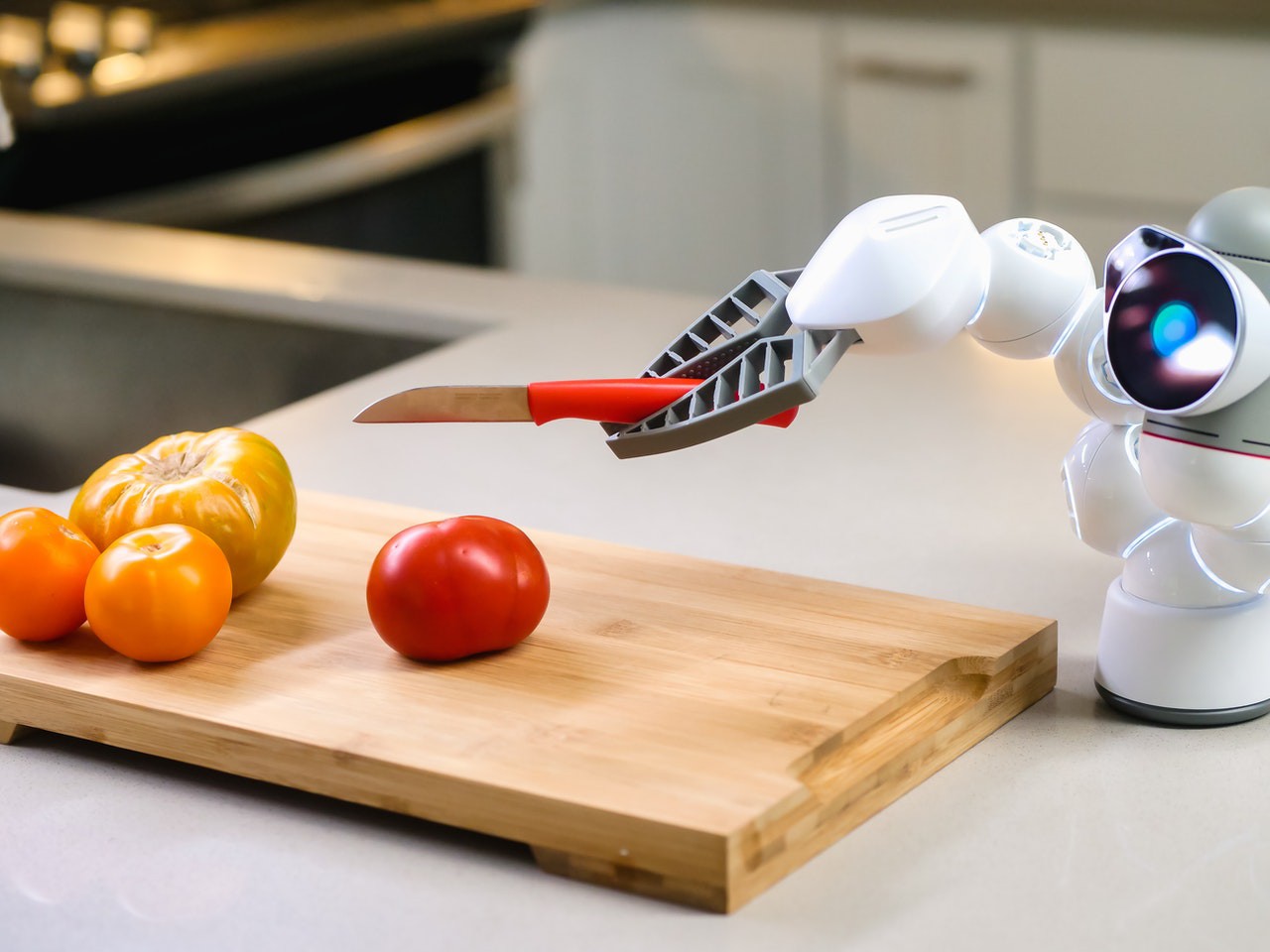

End-of-arm tooling is the technical term for robotic gripper technology. This refers to the part of a robotic arm that directly interacts with objects. There are various end effectors, each specific to a different purpose. For example, a popular type of end effector is the jaw gripper. These are similar to a claw in appearance and are generally used to pick things up. Engineers have created dozens of specialized end effectors to fit virtually every circumstance imaginable.

The end effector is the most crucial part of a robotic arm. Without the right EOAT, it won’t be able to do its job. It would be like trying to pick something up without using any hands, which is why end-of-arm tooling technology is a critical element of every area of robotics. It can be found on everything from robots assembling cars to rovers exploring Mars and the moon.

Types of End Effectors

Specialized end effectors are available to serve many unique purposes. Robotics has become a large field, especially as automation has become a trend worldwide. In response, engineers have created significantly more end effector designs over the years.

When engineers decide which specific end effector to use, they have to carefully consider what they need it to do. Robotic arms are used to simulate humans. Likewise, the end effector is used to simulate a hand. What will it need to grab? What will that object be made of? How delicate is it? These questions help pinpoint the best end effector for the job. Usually, it is one of a few main types.

Grippers

By far, the most common type of EOAT is grippers. There are several kinds, but most have a clawlike shape. The number of fingers and joints on the claw depends on its usage. The two-jaw gripper only has two fingers, while an o-ring gripper can have six or more. Bellows grippers have no fingers but a simple ring that expands and contracts.

The many options for grippers are part of what makes them so popular. They are easily adapted to do many jobs without getting too complicated. Gripper end effectors are most common in industrial automation as robots frequently pick up components to assemble or move parts down an assembly line. The grippers often use electric or pneumatic power.

Welding

Welding is a critical part of the assembly process for thousands of items. From construction to manufacturing, many industries rely on fast, quality welding. End effectors have been specially designed to serve this purpose. These EOAT devices are made for automating arc and spot welding and usually take the form of a modified torch.

Vacuum

Standard claw grippers are versatile, but sometimes they aren’t gentle enough. Vacuum end effectors are often used when this is the case. These EOAT devices use vacuum or suction contacts to “stick” to objects rather than clamping around them. Vacuum end effectors are typically found in automated packaging, where they can pick and pack items with a gentle touch.

Magnetic

Magnetic EOAT is similar to vacuum EOAT but specifically designed for paramagnetic and ferromagnetic objects, such as iron, steel and nickel. These end effectors use one of two types of magnets to pick things up: permanent magnets and electromagnets.

Permanent magnets are the most common everyday magnet. They are always magnetized, and objects must be manually removed from them. Electromagnets are created by running an electrical current through a certain kind of wire. Releasing things from the electromagnet is as easy as switching off the electrical current powering it. This makes them ideal for EOAT devices.

Robot vs. EOAT

Choosing an EOAT device can be challenging. Is it best to start by selecting a robot or an end effector first? Experts say prioritizing the end effector is the right strategy. While robotic arms all have slightly different features, they vary much less than end effectors do. The EOAT also directly impacts how well the robotic arm performs. Even the best one in the world would be completely ineffective without the right end effector.

This is especially true when it comes to collaborative robots, or cobots. These robots are designed to work alongside humans. They must do their jobs with precision and consistency, which requires a carefully selected end effector. Humans working closely with these cobots makes safety a much greater concern. Engineers need to consider what end effector will be most helpful to the people working with the robot. From there, they can find the safest model of the EOAT device they want and choose a compatible robotic arm.

Innovations in End-of-Arm Tooling Tech

End-of-arm tooling is a critical part of the modern robotics industry. It’s no wonder that many engineers specialize in creating new EOAT technologies. Several innovative end effectors are on the rise, and they hint at where the industry is going and what advancements could be coming next in robotics.

For example, the Internet of Things, or IoT, changes how analog devices connect to the world. IoT enables end effectors to be connected to larger robotic systems and sensor devices through the internet. Sensor-equipped end effectors allow engineers and robot operators to closely monitor the objects the robot is handling. They can use the sensors to collect data over time, which can be used to analyze and optimize the robot’s performance.

Another incredible recent development in EOAT is soft grippers. They are designed for handling objects that require an especially gentle touch, such as food. Many soft grippers are modeled after the human hand, which can hold things firmly and delicately at the same time.

The Key to Robotic Arm Technology

End-of-arm tooling is key to the success of any robotic arm design. Without the right end effector, the robot won’t be able to perform at top capacity. The world of EOAT is full of innovative designs that have the same goal: simulating the incredible engineering of the human hand.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post