BuildSteel is tracking the sustainability initiatives of Steel Framing Industry Association (SFIA) members and their partners. Here is some recent sustainability news related to the cold-formed steel (CFS) framing industry.

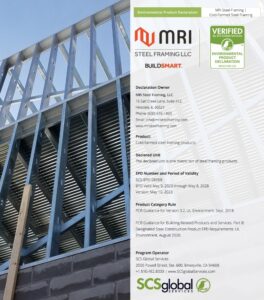

MRI Steel Framing Releases EPD

SFIA member, MRI Steel Framing, has published an Environmental Product Declaration covering its full line of cold-formed steel (CFS) framing products.

This EPD has been externally reviewed and verified, allowing MRI’s products to contribute 150% of the product under the LEED v4.1 standard, according to the MRI website.

The EPD offers a transparent, objective report that communicates what a product is made of and how it impacts the environment across its entire life cycle. Architects and engineers increasingly specify products with transparent LCA-based environmental impact reports.

Download the MRI Steel Framing EPD.

U.S. Steel to Capture Greenhouse Gas Emissions

United States Steel Corporation, a leading steel producer and an SFIA member, and NETL recently announced a plan to test an advanced membrane technology to capture carbon dioxide emissions generated by steelmaking operations at the Company’s Edgar Thomson Plant, located in Braddock, Pennsylvania.

The project is part of the U.S. Department of Energy/NETL Point Source Carbon Capture Program. Point source carbon capture from industrial facilities, such as iron and steel manufacturing plants, is a vital element to reduce CO2 emissions and meet the nation’s climate change goals. Carbon capture has the potential to reduce CO2 from blast furnaces.

“This is an opportunity to play a role in shaping the future of greenhouse gas reduction for the entire steel industry,” said Scott Buckiso, senior vice president and chief manufacturing officer, North American Flat-Rolled Segment, U.S. Steel. “Our collaboration with NETL marks a great step forward in U.S. Steel’s ambition to achieve net-zero by 2050.”

PROVE IT Act to Bolster Transparency of Global Emissions

The American manufacturing sector has invested significantly in cleaner and sustainable production technologies, aiming to reduce their environmental impact, according to RealClear Energy.

“The American steel industry has the lowest CO2 emissions per ton of steel produced of any of the major steel-producing countries and accounts for just 1-2% of U.S. greenhouse gas (GHG) emissions,” said Kevin Dempsey, president and CEO of the American Iron and Steel Institute. “Globally, the steel industry emits around 8% of total world GHG emissions.”

“But unless companies overseas do the same,” Dempsey adds, “American manufacturing’s commitment to sustainability will put us at a disadvantage. This is because the U.S.’s higher environmental performance comes with costs that many of our competitors are exploiting to capture global market share.”

To address the threat posed by unequal environmental standards, there is a need to level the playing field. However, the U.S. government and policymakers currently lack the necessary data to advocate for action.

Thus, the U.S. Senate Environment and Public Works Committee is considering a new policy initiative called the PROVE IT Act, “Providing Reliable, Objective, Verifiable Emissions Intensity and Transparency.” It would create an official source to verify the superior carbon efficiency of vital American industries, like steel.

“PROVE IT will help demonstrate that policies in support of U.S. manufacturers are also policies that lower global emissions,” said Dempsey. “But the clock is ticking. Without data, we risk handing control of our narrative—and our economic success—to foreign governments.”

Additional Resources

- Update #14 | Sustainability News from Cleveland-Cliffs, U.S. Steel, and Nucor

- Update #13 | Sustainability News from ArcelorMittal Dofasco, U.S. Steel and Nucor

- Update #12 | Sustainability News from Nucor, U.S. Steel, and Steel Dynamics

- Update #11 | Sustainability News from Steel Dynamics, Cleveland-Cliffs and Carnegie Mellon

- Update #10 | Sustainability News from ArcelorMittal, U.S. Steel and Nucor

- Update #9 | Sustainability News from Nucor, Cleveland-Cliffs and U.S. Steel

- Update #8 | Sustainability News from FrameCAD, Cleveland-Cliffs and ArcelorMittal Dofasco

- Update #7 | Sustainability news from ArcelorMittal, SDI and U.S. Steel

- Update #6 | Sustainability news from Cleveland-Cliffs, Worldsteel and U.S. Steel

- Update #5 | News from Nucor, Cleveland-Cliffs and a New Low-Emissions Steel Coalition

- Update #4 | Steel Framing Industry Sustainability Initiatives

- Update #3 | Steel Framing Industry Sustainability Initiatives

- Update #2 | Steel Framing Industry Sustainability Initiatives

- Update #1 | Steel Framing Industry Sustainability Initiatives