Photo Credits: Form Found Design

Los Angeles-based architectural firm Form Found Design successfully completed a prototype home for a groundbreaking humanitarian housing project in Yerevan, Armenia. Home of Hope is a prototype of modular, mass-customization using cold-formed steel (CFS) framing. The housing project serves a humanitarian need by providing durable shelters for impoverished families in Armenia.

With a single roll-forming machine, an international construction team was able to design, roll form and assemble the CFS studs, track and joists for a custom home in only three days.

Form Found Design successfully completed a prototype home for a humanitarian housing project in Yerevan, Armenia. Photo Credit: Mighty Oakes Productions, 2023

Rapid Home Design and Production

Joseph Sarafian, CEO and co-founder of Form Found Design, along with co-founder Ron Culver, led an exploration of alternative materials and technologies for the Home of Hope project. The Form Found Design team preferred how light gauge steel could serve the immediate need for housing, according to the website designboom. The Home of Hope Initiative, by the Armenian Relief and Development Association, is led by Ariel Babikian.

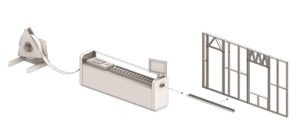

Steel framing, produced with a FRAMECAD machine, presented an avenue for rapid design and production of many houses. The roll-forming technology streamlines the process by unrolling steel coils and transforming them into custom-sized studs. FRAMECAD, an SFIA member, offers an end-to-end steel building system for the engineered design, roll-forming and construction of CFS structures.

The steel stud roll-forming machine above (system diagram below), from SFIA member FRAMECAD, streamlined the building process by unrolling steel coils and transforming them into custom-sized steel studs.

Steel Framing: No Cutting, No Waste

According to Form Found Design, every steel stud and track is custom cut, labeled and punched. There is no cutting or waste on-site.

The software generates assembly drawings in the form of cut sheets that workers can reference as they assemble the walls, floors, and roof trusses.

The FRAMECAD software generates assembly drawings that workers can reference as they assemble the walls, floors and roof trusses.

The Home of Hope Team

The modular Armenian home framed in 3 days is also equipped with solar panels as well as solar hot water heating to serve the family of five. A team of international consultants collaborated to deliver this project.

The Home of Hope consultants included:

- Students from Orange Coast College

- Students from Armenia

- FRAMECAD consultant, Csteel, based in Melbourne, Australia

- Antioch Investment SRL, a fabricator located in Romania

- Walter P Moore, an engineering consultant

- Simpson Strong Tie, an SFIA member that donated all metal brackets

The modular homes are equipped with solar panels and solar hot water heating. Photo Credit: Mighty Oakes Productions, 2023

Second Home Framed, More Planned

Home of Hope represents the first modular CFS framed humanitarian housing project in Armenia. Form Found Design has now seen their second Home of Hope framed in Vanadzor, Armenia. This home was also built rapidly using the FRAMECAD system. Four more homes have been printed and are ready for assembly as part of a planned development in Vanadzor.

The need for housing in Armenia has exploded with the influx of Russian citizens fleeing Russia to avoid being drafted during the invasion of Ukraine. In September, this need increased even more when over 100,000 indigenous Armenians were forcibly displaced from their ancestral homeland of Nagorno-Karabakh (Artsakh) in an effort by Azerbaijan to ethnically cleanse the region. With the influx of these Armenians in the country, the need for rapid housing production has skyrocketed and light gauge steel production through systems like FRAMECAD could pave a way to solving the need in this earthquake-prone region.

Steel framing provides an option to quickly build housing for the 4,000 families living in temporary, shanty shelters in Armenia.

Additional Resources

- FRAMECAD Launches Residential Steel Framing Customer Service Center

- Frame Up Now, Empowered by FRAMECAD, Says Cold-Formed Steel Will Replace Wood in 15 Years

- New Data May Change Building Codes and Help Prepare for Future Disasters