While the fashion in high-tech automotive developments might lean towards hybrids and electric vehicles at the moment, there’s still plenty of scope to improve the good old internal combustion engine and one of the holy grails of such development is the creation of a viable variable-compression-ratio system.

Now Porsche is working on just such an engine, revealed in the form of a newly-published patent, which will be able to alter its compression ratio. It’s partner in the project is engineering firm Hilite International, a leading maker of engine components including variable valve timing cam phasers.

Why is a variable compression system so desirable? Because, particularly when allied to a turbocharged engine, it has the potential to maximize economy and efficiency while simultaneously improving outright performance.

While turbos are great when it comes to allowing relatively small-capacity engines to produce giant-killing performance, they do require a compromise in terms of compression ratio. To accommodate the increased volume of intake charge that the turbo supplies at full boost, a turbo engine needs a relatively low compression ratio, which in turn means they can be lethargic when boost levels are low. Increasing the compression ratio towards that of a normally-aspirated engine helps that low-speed performance, but means peak boost needs to be restricted because forcing more air and fuel into the cylinder means the effective compression ratio is increased – if it gets too high, the result is detonation, which is usually just as bad for the engine as the name suggests.

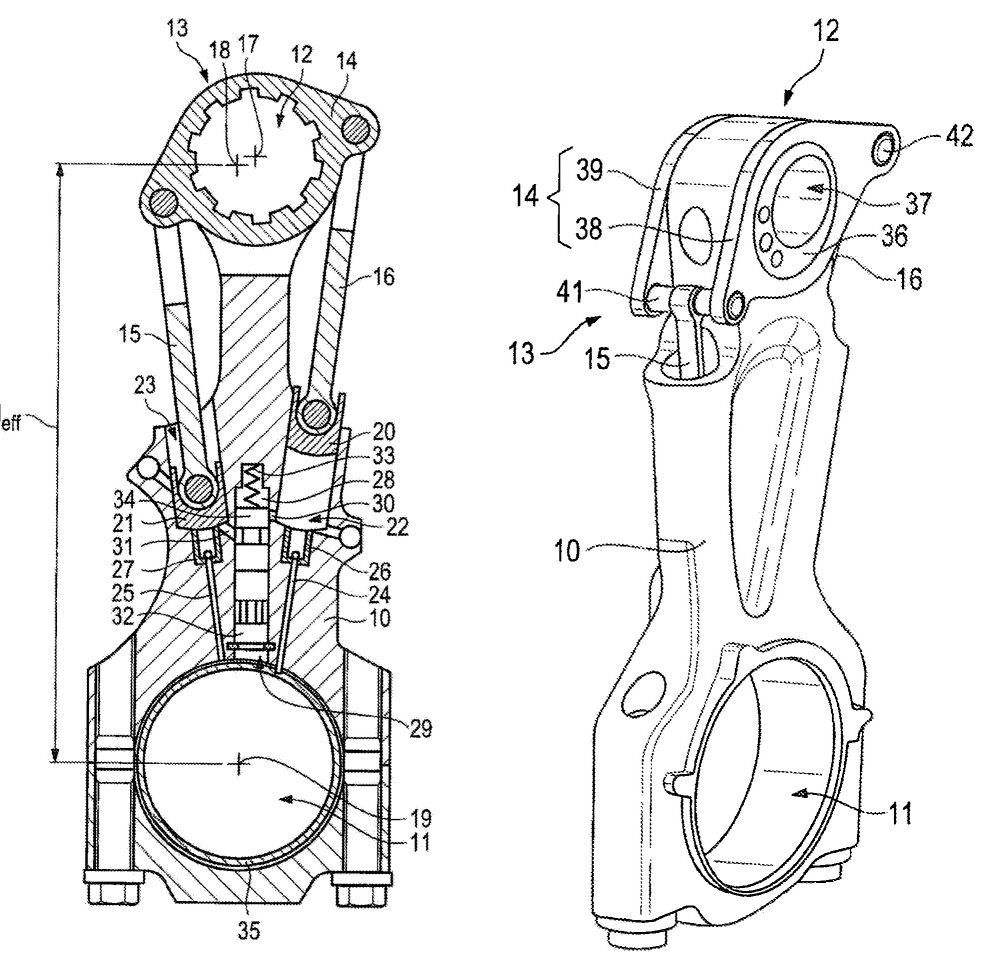

By varying the compression ratio – in this case by putting the small-end bearing into an eccentric adjuster, automatically tilted by oil-pressure-activated rods either side of the con-rod – the idea is to be able to use relatively high compression ratios with low levels of boost, effectively making the engine behave like a small, normally-aspirated design. When needed, swiveling the eccentric adjuster moves the piston down a fraction reduces the compression ratio and allows the engine to cope with far greater levels of boost, resulting in massively increased power.

On the Porsche system seen here, a solenoid directs oil to one of two rods, rocking the eccentric small end bearing holder into either a "high compression" or "low compression" position. The technology is very similar to that used in oil pressure operated variable valve timing systems.

Porsche and Hilite aren’t the first to attempt to make a variable compression engine, but the two firms seem to have struck upon a relatively simple, compact and workable method of doing it. A huge question mark still hangs over whether the resulting engine will be cheap, effective and reliable enough to reach production, but it’s clearly a step in the right direction.

Finally, it’s worth noting that much of Porsche’s work is in the form of engineering consultancy, so the fact the firm’s name is on the design’s patent doesn’t mean the engine is being developed for a new Porsche-branded car; it could just as easily appear in a machine from another firm.